Technology & Innovation

Oil India Limited has been pioneering the use of new and advanced technologies & knowledge in its Upstream and Midstream activities over the decades. OIL endeavors to induct state-of-the-art and fit-for-purpose technologies encompassing all the domains of Hydrocarbon Exploration, Development, Production & Transportation.

OIL is also proactive in adopting digitalization and automation across its operations. Through the integration of IoT sensors, data analytics, and AI-driven predictive maintenance systems, the company ensures the reliability and longevity of its assets while reducing downtime and operational costs.

Overall, Oil India Limited's focus on technology and innovation underscores its commitment to remain at the forefront of the oil and gas industry while addressing the evolving challenges of energy exploration and production in a sustainable manner.

Technology providers can directly approach OIL's user departments or can submit online any time all through the year. OIL's user departments will continuously scrutinise the direct & online submissions and invite the shortlisted fit-for-purpose technology providers to discuss the technologies and its induction feasibility.

For any queries, please contact: oil_tech_induction[at]oilindia[Dot]in

Register

1. eRTMAC

OIL’s Real time data monitoring and analysis center is equipped with state-of-the-art technologies to monitor the various drilling operations in real time with advanced visualization platform and cutting-edge sensor technology. It includes transmission of real time critical well data to the command center.

The Centre is monitored round the clock by Skilled Engineers who analyse the data and make real time decisions and ensure the safety and efficiency of drilling operations.

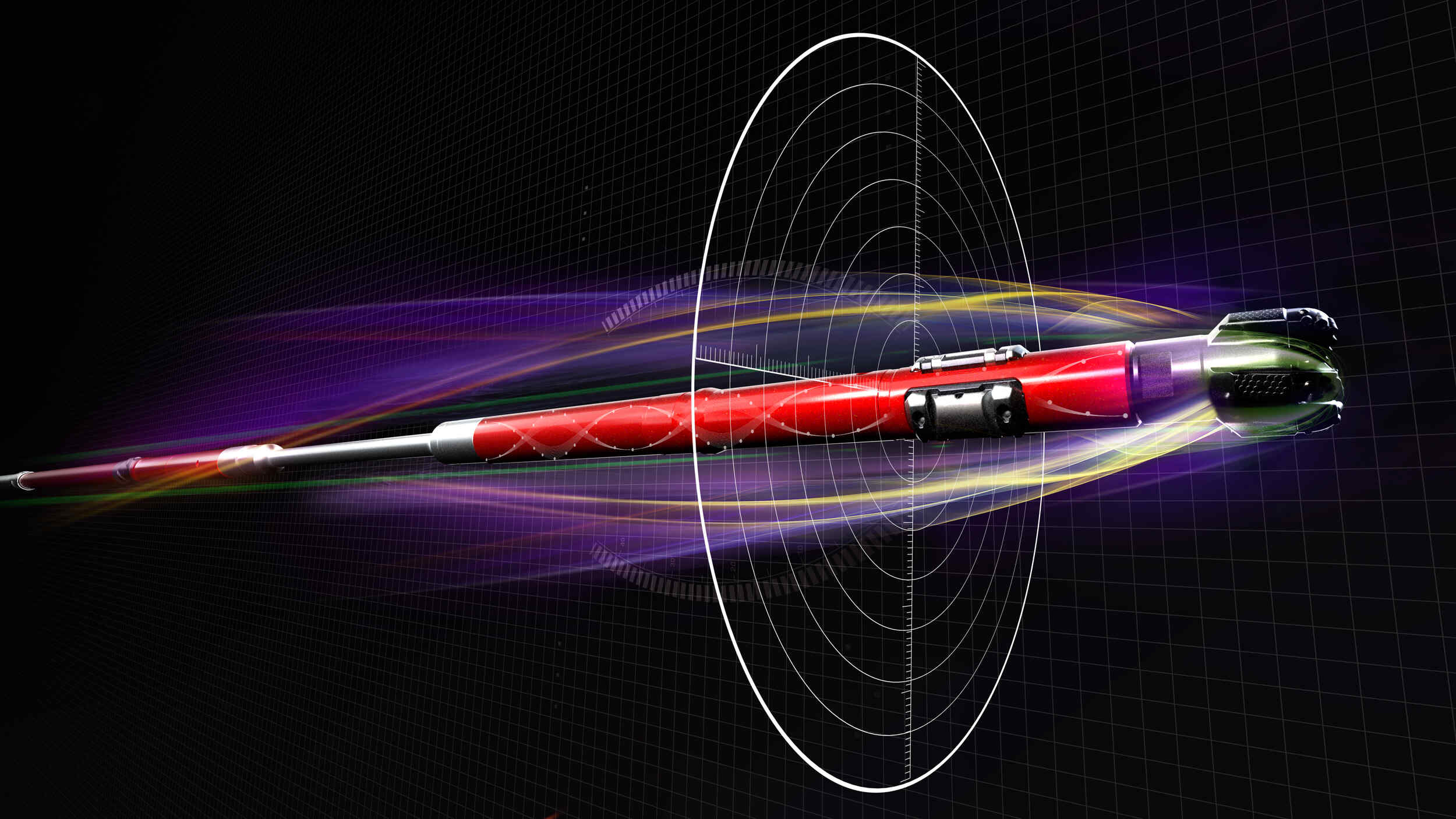

2. Advanced RSS (Rotary Steerable System) with LWD (Logging While Drilling)

The majority of the wells drilled by OIL are highly deviated in nature. The Company is aggressively incorporating cutting edge technologies for enhancing drilling efficiency and performance.

With the incorporation of sophisticated tools such as RSS (Rotary Steerable System) along with Advanced LWD, the drilling efficacies have increased manifold due to precise Steering control, enhanced drilling speed, reduced well tortuosity and accurate well placement along with real- time data acquisition and evaluation.

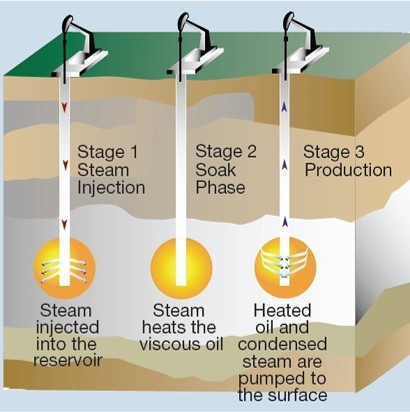

1. CYCLIC STEAM STIMULATION IN RF:

With successful induction of Cyclic Steam Simulation(CSS) technology in the year 2018, the first of its kind in India, OIL has claimed a breakthrough for extraction of heavy crude oil from Jodhpur Sandstone after almost 27 years of its discovery. Full-scale production of heavy oil discovered from the oldest sedimentary rock of Rajasthan is now becoming a reality with the success of CSS, leading to a highest ever daily crude oil production from Rajasthan Fields of 642 bbls in FY 2023-2024.

With successful induction of Cyclic Steam Simulation(CSS) technology in the year 2018, the first of its kind in India, OIL has claimed a breakthrough for extraction of heavy crude oil from Jodhpur Sandstone after almost 27 years of its discovery. Full-scale production of heavy oil discovered from the oldest sedimentary rock of Rajasthan is now becoming a reality with the success of CSS, leading to a highest ever daily crude oil production from Rajasthan Fields of 642 bbls in FY 2023-2024.

CSS is a thermal EOR process in which a predetermined amount of high temperature steam (250-320 deg C) is injected into a producer oil well through VIT (Vacuum Insulated Tubing).

The well heads where CSS application are used are thermally completed capable of resisting the high pressure and high temperature steam. The injection phase into the well continues for about 14 to 21 days based on reservoir injectivity. The well is then shut in for a few days approximately 50% of injection days whereby the heat content of the steam is allowed to soak in the producing formation around the well bore. The steam temperature heats the formation & reservoir fluid around the well bore which in turn reduces the viscosity of the oil and enhances its mobility and production. The well is then put on production phase. Initially the well flows self and when the flow ceases SRP surface unit is installed to recover the stimulated fluid. The production phase continues till the stimulated fluids are produced and when the well returns to its cold production level, the next cycle of CSS begins. The cycle of soak- and-produce, or "Huff-and-Puff" is repeated till the cycle reaches its economic limit.

CSS as a thermal EOR has shown encouraging results in OIL-RF with production enhancement by 40-60% in comparison to cold production. In Nov 2018, the first CSS cycle was carried out in BGW#08 (Pilot thermally completed well). Since then, OIL-RF has successfully carried out CSS in 12 numbers of wells. The total CSS cycles executed till date is 29. Currently, a total of 09 wells have been thermally completed with Vacuum Insulated Tubing (VIT) and Thermal Wellhead. FY 2023-24 has seen the highest number of CSS cycles executed till date in a single financial year, with 3 CSS cycles through our In-House OTSG Boiler and 8 CSS cycles through hired boiler. In FY 2022-23, a total of 9 CSS cycles were executed both through inhouse and hired boiler.

The Cyclic Steam Stimulation has three phases –

- Steam Injection Phase

- Soak Phase

- Production Phase.

2. PLUNGER LIFT IN EASTERN ASSET:

Plunger lift is an economical rig-less artificial lift system applicable to high gas-liquid ratio gas wells and gas lift wells, which was deployed in various marginal fields of Oil India with the primary objective of extending the economic lifespan of the wells. The project involves plunger lift installation, optimization, of plunger lift system for gas wells and intermittent gas lift wells.

Plunger lift system installed in gas and intermittent gas lift wells have benefits like - Improved drawdown and maximized flow potential, Cyclic de-liquification of gas wells, Stabilized gas and liquid flow, Increased overall efficiency of the gas lift system, Resumption of a normal decline curve, Increase the economic lifespan of the well and Delays high CAPEX expense of other artificial lift system methods.

This hybrid project was successfully executed to increase oil, condensate, and gas production in addition to reducing paraffin deposit-related issues, compression horsepower, and overall operating expenditure while maintaining an optimized injection gas rate. This plunger lift project resulted in an overall average of 36% liquid and 83 % gas gains in the candidate wells of the Oil India.

3. POLYMER FLOODING IN SECONDARY RECOVERY :

Oil India Limited identifies Enhanced Oil Recovery (EOR) as one of the strategic focus areas to increase reservoir oil recovery. OIL - in its continued effort for augmenting production from its ageing fields - has been giving thrust since recent past on Enhanced Oil Recovery (EOR).

For evaluating and developing an appropriate chemical EOR strategy for reservoirs in Greater Naharkatia Field, OIL took up a study and initiated steps to carry out polymer flooding on a pilot basis in Naharkatia Field by utilizing two inverted five (5) spot patterns - each pattern consisting of one (1) injection well and four (4) production wells. Two new injector wells have been specifically drilled for this purpose.

Since then, continuous injection of polymer solution is going on in both the injectors using PHPA (Partially Hydrolysed Polyacryl Amide) polymer at a viscosity of 25 cP.

In exploration, OIL’s Geoscience & Geology Group employs cutting-edge seismic imaging techniques, such as 3D seismic surveys and advanced geological modelling, to identify potential hydrocarbon reserves accurately. These technologies help minimize exploration risks and optimize resource utilization during the actual drilling.

Centralized Core Repository of OIL in Guwahati

The Centre of Excellence in Energy Studies (CoEES), OIL has initiated the process of construction Core Repository building with advanced laboratory facilities in Narengi, Guwahati – a first of its kind in South-East Asia. It is projected that this will entail the preservation of conventional cores, drill cutting samples, laboratory analysis, digital imaging of core, core viewing, digital archival system, etc. Under this centralized Core Repository, it is envisioned that all extracted conventional cores and cuttings from different spheres of OIL and other agencies operating in India will be preserved to ensure the efficacy of all geoscientific and engineering studies, which is essential for basin analysis and prospect identification for hydrocarbon exploration and enhancement of the field development process.

Rockwash Geodata

Oil India Limited in collaboration with M/s Rockwash Geodata has newly inducted the latter’s patented technology for methodical cleaning of rock samples/drill-cuttings of wells which lays the foundation for the subsequent collection of reliable data from the wells that have a vital role to play in addressing uncertainties in modern subsurface analysis.

The key components of M/s RockWash Geodata's technology include:

Digitalization of physical Drill Cutting samples and Well Information into digital formats for easy analysis, maintaining a cloud-based database ensuring easy storage, retrieval, and accessibility.

Quick decision-making aid with deeper understanding of the subsurface geology and reservoir rock properties.

Seamless integration with existing data creating a comprehensive and unified database.